Crushing, Mixing, Processing

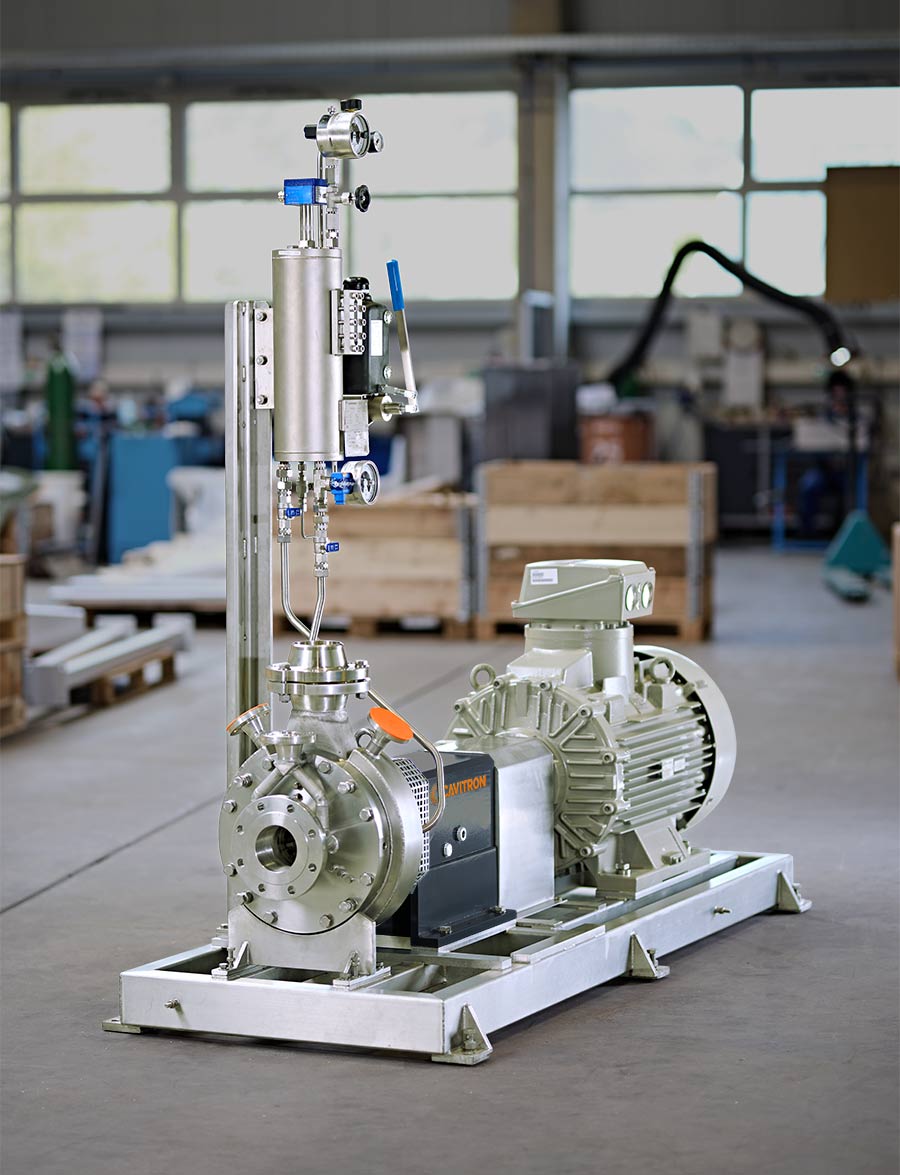

The mixing and crushing machines of the Cavitron CD type are designed for the production of liquid mixtures and solids in liquids. They process products across a wide range of viscosities. The various sizes allow a throughput between 300 liters and 100 cubic meters per hour.

Cavitron CD machines are used in all industries that process liquid and solid dispersions. In the chemical industry, the machines are used as continuous reactors due to the hugely increased mass transfer. This is based on a massive enlargement of the phase boundary surface, the highly turbulent shear field, and the high specific energy input in the machines.

Extremely wear-resistant materials such as Hastelloy, titanium, or other special materials are used as standard in the machine construction, as well as 1.4301 or 1.4571. All machine types, including laboratory machines, have been tested in continuous industrial use.

Applications

Cavitron CD machines deliver excellent results for mixing, emulsifying, dissolving, wet grinding, homogenizing, and neutralizing, as well as for catalytic reactions, polymerization, rearrangements, shear treatment of cells, initiation or execution of physical and chemical reactions, continuous cooking processes under shear stress, and using direct steam.

Special Features

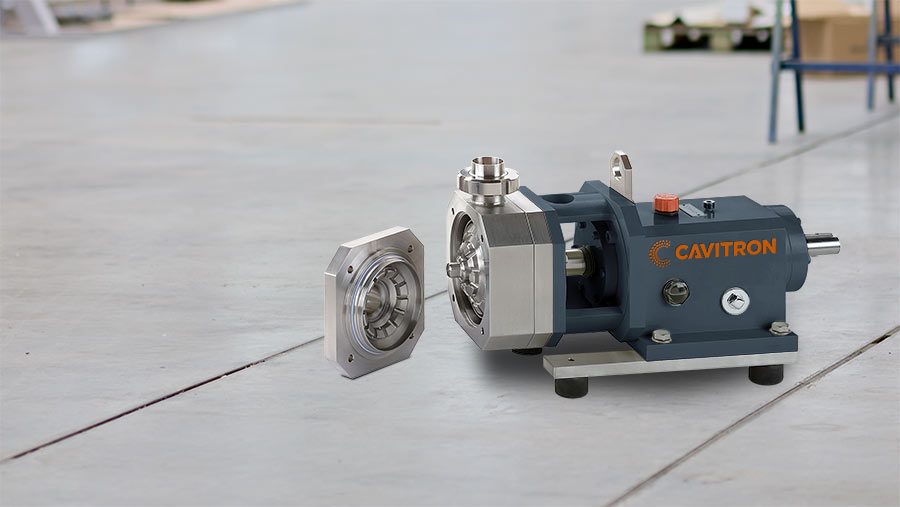

- Cavitron CD machines offer a wide selection of different rotor-stator systems for a variety of applications.

- Combining various processing steps in one machine can achieve significant rationalization. This minimizes production times, eliminates some subprocesses entirely, and significantly reduces production costs. The immediate and complete dissolution of raw materials ensures quick and reproducible product manufacturing.

- Compared to batch production, the required work area is about 90% smaller. There are no containers with joints nor any built-in parts. Forced feeding through the machine guarantees 100% processing. Pressure and temperature are better controlled in the small volumes of the machine than in stirred tanks.

- In the rotor-stator system of the Cavitron CD, the product flows through extremely small processing zones, which means lower energy consumption compared to container processes.

- Cavitron CD machines are completely safe and environmentally friendly, as no dust escapes into the atmosphere. The entire dispersion process takes place in a closed process chamber, making it emission-free. Our technology can work with higher solid contents and higher concentrations, so fewer fluids such as water or solvents are needed.

General Specifications

Continuous throughput: 0,3 – 100 m³/m

Rheology: pumpable fluids can be processed

Electrical connection: 2,2 – 230 kW

Weight: 30 – 2.000 kg

Intensity: variable through the exchange of rotors and stators as well as automatic speed adjustment.